Making Your Joinery Factory Lean and Efficient: Key Strategies

Published: September 1, 2025

Craftsmanship is at the heart of boutique kitchens. But the difference between a day of hustle and a week of harmony is often the system behind the sawdust.

There are lots of measures that you can apply to joinery, but improving one measure can perhaps have more impact than any other. That is, the lead time from receiving raw materials to shipping finished quality product to your customer. Lead time matters in so many ways.

We asked the audience about this and these are their statements.

Culture First Efficiency isn’t won by machines alone; it’s won through culture. As Paul Dunlop wisely observed:

“Providing a work environment where people are valued, enabled, meaningfully engaged and supported appropriately… That only happens with a servant leadership model built on respect, values, and psychological safety.”

In our workshop, we’re building trust, not pressure. Because sustainable improvements come from empowered people, not fear.

Better Flow, Smarter Batches Optimising batch size is crucial to seamless production. Industry expert Bobbo Buckley’s advice hits the mark:

“One‑piece‑flow (or at least small batches and tiny transfer batches).”

Our CNC nesting helps balance yield with better flow, shorter queues, fewer bottlenecks, cleaner handoffs between stations.

Three Pulses, One Healthy Business Bruce R Poling likens business health to a heartbeat—steady, responsive, monitored. Here are the three pulses we now check daily:

1. Improvement Pulse – Small daily changes are as vital as getting the job done. Continuous progress keeps us lean.

2. Production Pulse – Avoid large work piles. Smooth, small-batch flow keeps momentum and clarity.

3. Money Pulse – Healthy cashflow isn’t accidental. It requires tracking, pricing, and timing that fuel what comes next.

Craftsmanship Meets Clarity Stylish kitchens and efficient joins aren’t mutually exclusive. By designing our layout, workflows and culture to support flow, we allow detail to shine, not stall. Clients get on-time delivery, teams get clarity and craftsmanship remains front and center.

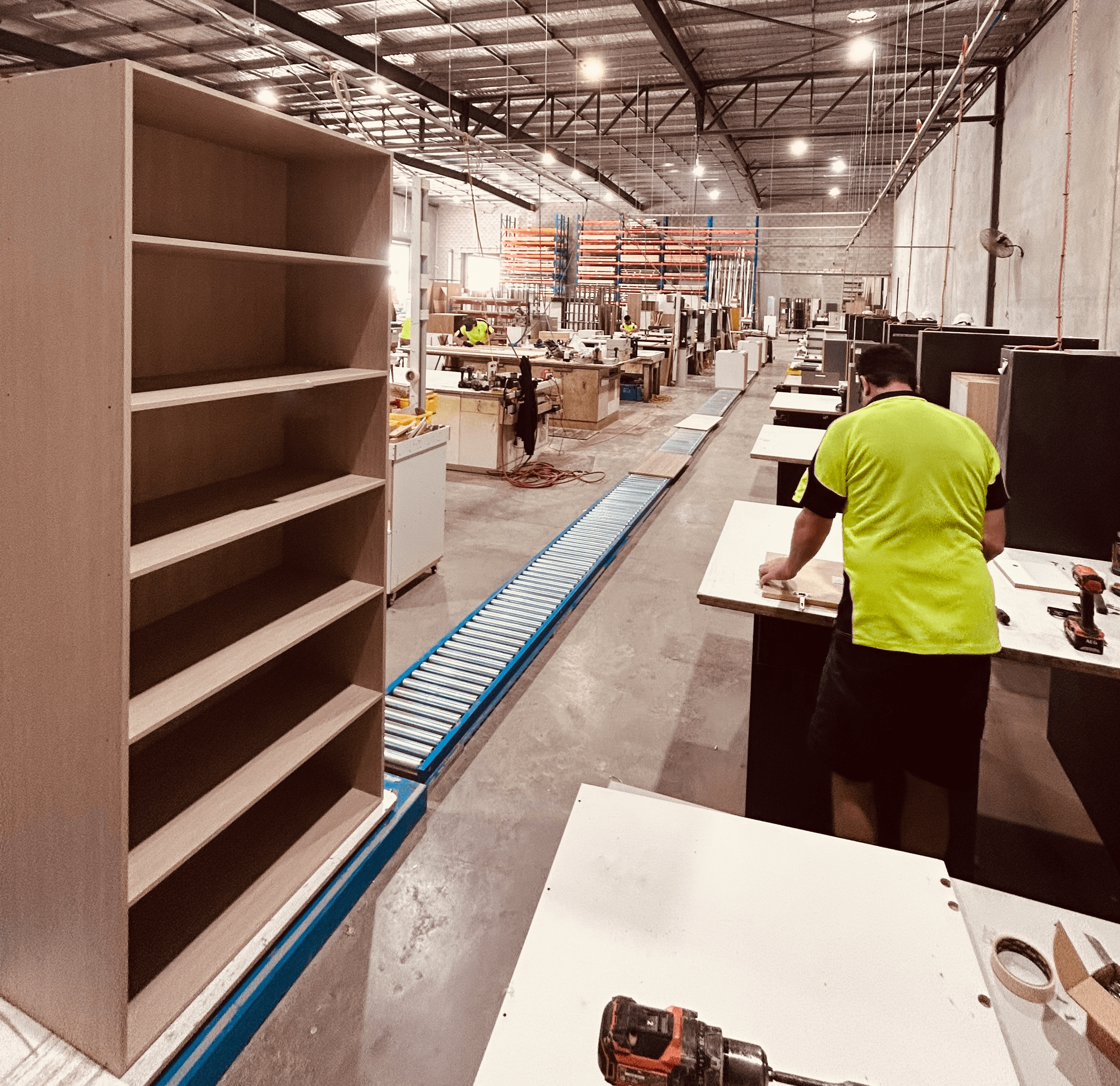

A Clean and Well Organised Workshop is an Efficient Workshop

A clean and well- organised workshop is not only efficient but also essential. With modern extraction systems and proper housekeeping practices, there is no need for a messy shop. Maintaining cleanliness ensures a healthier workplace, improves productivity and prevents hidden machine issues that could lead to costly breakdowns. Ultimately, order in the workshop supports both quality craftsmanship and long-term success.

In conclusion, efficiency in joinery is more than machines and materials—it is culture, flow and discipline working together. By reducing lead times, empowering people, optimising batch sizes and maintaining a clean well-organised workshop we create an environment where craftsmanship thrives and quality never falters. A lean and efficient factory does not just deliver kitchens it delivers trust, reliability and long-term success for both clients and team members.

What’s Your Pulse? How do you balance art and process in your workshop? I’d love to hear. Drop a comment below.

Boutique Kitchens & Joinery — where intention meets execution in every custom piece.